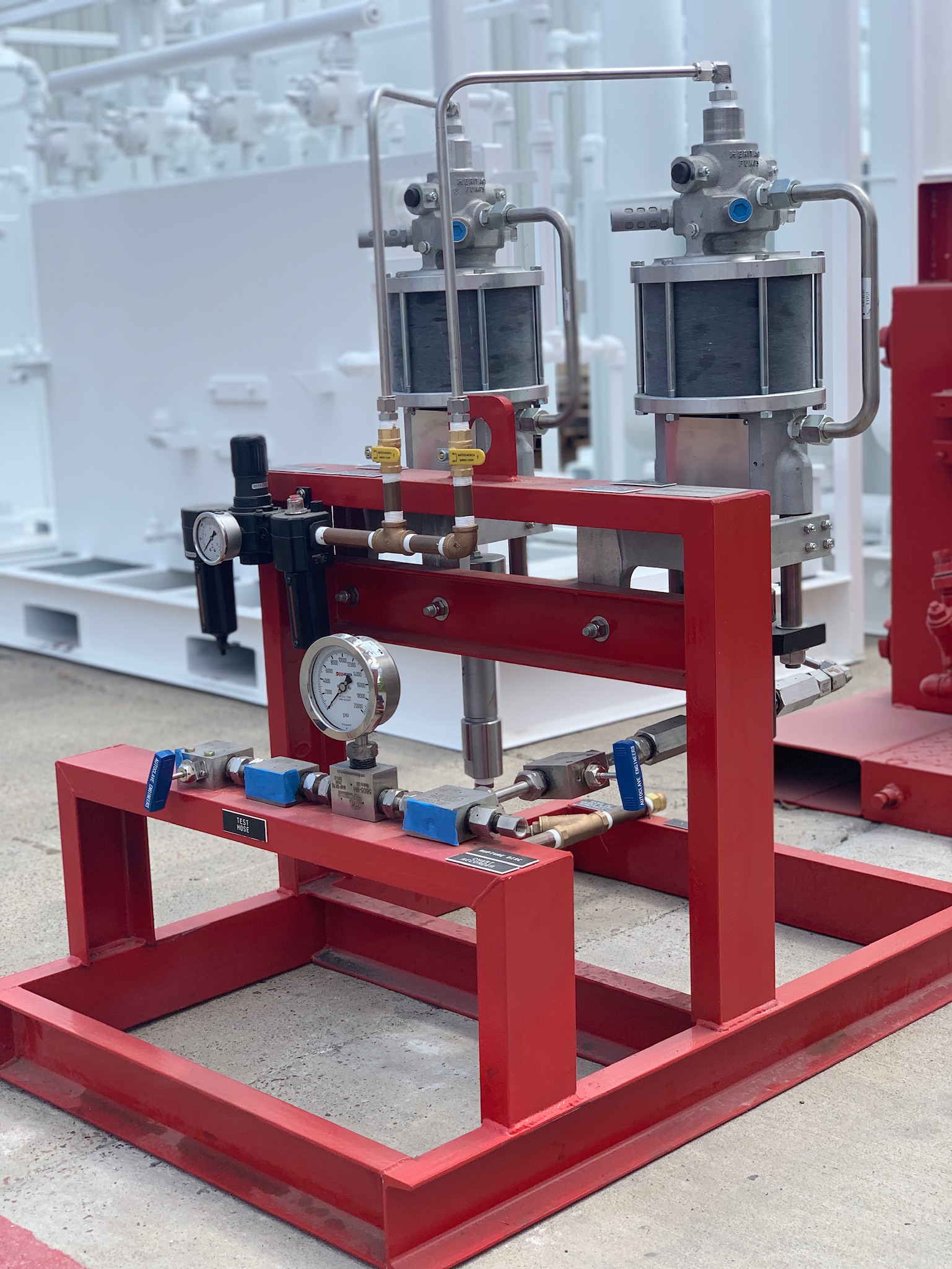

Hydrostatic Pressure Testing Equipment

MEYER’s Hydrostatic Shop Test Units are engineered to quickly and safely test pressure in BOPS, wellheads, and valves in a controlled shop environment. Electrical, diesel, gas, and air-powered hydrostatic valve testing equipment is available and we offer optional remote panel operation. Our hydrostatic pressure test equipment increases operator safety by removing pressure hazards.

Standard Features

- Electric motor power: explosion proof or industrial

- Dual air motors

- 60:1 higher volume and pressures up to 5,000 psi

- 200:1 Secondary pump pressure up to 20,000 psi

- 30,000 psi gauge

- 20,000 chart recorder

Controlled Hydrostatic Pressure Testing

Hydrostatic pressure testing in a controlled shop environment is important to verify that the components being tested are ready to be transported for installation into the field. With our controlled hydrostatic pressure tests, we verify the current integrity of new and old pipes by detecting any leaks or losses of pressure.

Controlled hydrostatic pressure testing with a shop test unit begins with filling vessels or pipelines with a liquid that is typically dyed to visually verify any leaks or pressure issues. Next, the pressure testing unit pressurizes the component being tested to a certain pressure, testing for any pressure loss. If there is a leak or loss of pressure, the test liquid helps to identify the location of a leak, allowing the technicians to properly diagnose and fix any pressure and leakage issues.

Hydrostatic shop test units are one of the most widely used processes for precisely testing pipes and pressure vessels in the oil and gas industry. Pressure testing in a controlled environment allows for the testing and verification of the quality of equipment, ensuring that each piece of equipment is aligned with safety regulations and protocols before being placed into the field. A controlled testing environment allows for safer hydrostatic pressure testing and more accurate diagnosis of issues, should any problems arise.

Additional Resources

Hydrostatic Pressure Testing Equipment Options

- Triplex pumps for higher volume and faster testing

- 30,000 psi secondary pump

- Electric motor

- Diesel motor

- Gas motor

- Air actuated remote bleeder valve to purge system

- Digital pressure readouts

- 10 micron stainless steel filter housing filters supply and return fluid

- Remote panel allows pump to remain in test booth while the operator remains safely outside

- Hydraulic system allows valves to be functioned from test stand - single station or multi station available

Hydrostatic Pressure Testing Equipment Rental

Let our expert staff work with you to engineer the right hydrostatic testing equipment for your application. We will work with you to size the hydrostatic pressure testing unit to API guidelines and build the unit to your requirements. Learn more about our hydrostatic pressure and valve testing equipment rentals.